A BRIEF HISTORY OF ALL-CLAD

In 1948, John Ulam graduated from the University of Pittsburgh with a metallurgy degree and worked in the industry for a number of years. In 1958, he founded Composite Metal Products, Inc., which specialized in bonded metals, and sold it a decade later. In 1967, Ulam founded Clad Metals Inc., which produced bonded metal coins for the U.S. Mint, as well as bonded metals for aviation. Clad Metals Inc. would come to be dominated by its subsidiary, All-Clad Metalcrafters (Canonsburg, Pennsylvania), the maker of what is now one of the best-known brands in American cookware: All-Clad. Ulam served as president of the privately-held company until November 1988, when All-Clad was sold off to Sam Michaels, an area businessman who subsequently sold the company to Waterford Wedgwood (Ireland), which in turn sold the company to French cookware conglomerate Groupe SEB. As of 2015, All-Clad is still an American subsidiary of Groupe SEB.

Ulam died of cancer on February 1, 1989, and I suspect that his illness and imminent death factored into why All-Clad was up for sale in 1988. If Ulam were still alive, I suspect that he would not have sold the company. Rest in peace, John. For those would like to know more about the history of the company, I moved that section to this post.

For those who want the quick answers to the title questions, here you go:

Q: Is All-Clad worth it? That is, is All-Clad worth the price?

A: Usually people ask this question when they hear good things about All-Clad D3 Stainless cookware but are hesitant about the price. That’s even after considering how the price difference between a mediocre pan and a good one can be spread out over an entire lifetime.

So is All-Clad D3 Stainless worth it? (Note: prior to 2018, All-Clad D3 Stainless was simply known as “All-Clad D3 Stainless.” These two names are used interchangeably throughout this site.)

Yes. All-Clad D3 Stainless is good quality and lasts a lifetime, so the cost per year of ownership is tiny. And according to a study by Johns Hopkins University, “[w]hen people cook most of their meals at home, they consume fewer carbohydrates, less sugar and less fat than those who cook less or not at all, even if they are not trying to lose weight.” Home-cooked meals even add to life expectancy. Home cooking is both less expensive and healthier than eating processed food or restaurant food (usually laden with salt/sugar/fat). Yet many people don’t cook at home as much as they could. Better cookware encourages home cooking by making it easier. Even small decreases in effort matter. For example, dieting studies have shown that people drink less using small glasses because it takes effort to refill.

Is it possible to get All-Clad D3 (also known simply as All-Clad Stainless) performance for less?

Yes. The cheapest knockoff of All-Clad D3 Stainless that still retains the same performance and features is Cuisinart MultiClad Pro (MCP), which costs much less. (I review it here.) The caveat is that it’s made in China and possibly less corrosion-resistant, but it’s apparently still very rugged–my heavily-used 3-quart MCP saucepan has given years of service (since 2010), with no trace of rust or pitting inside.

Also, All-Clad D3 Stainless is not “the best” product line out there, and if your budget is high enough for All-Clad D3 Stainless, you have other options that may spread heat more evenly, are easier to clean, have more comfortable handles, etc.

So I’d say All-Clad is worth it, but you could be better off with other brands, depending on your needs and budget. We’ll go over alternatives to All-Clad, below.

Q: Is All-Clad still made in USA? What are the differences between All-Clad product lines?

A: It depends on what product line you are talking about:

All-Clad Made in China

All-Clad’s policy regarding its cookware is that single-layer products such as lids are allowed to be made outside of the USA, typically in China.1 That might explain why some All-Clad lids are not 18/10 but rather something more like 18/0. Multi-layer metal cookware (i.e., has thick sidewalls made from steel bonded to another metal) is always made in the USA, with the exception of now-discontinued Emeril Pro-Clad and its equally-flawed successor. Emeril Pro-Clad was a thinner All-Clad D3 Stainless variant with glass lids. It was made in China and was overpriced compared to other companies’ China-made All-Clad knockoffs.2

All-Clad Made in USA

All-Clad made in America is high quality. Furthermore, All-Clad is a profitable entity that shows no signs of going bankrupt anytime soon, so its warranties are actually worth something. There are several major product lines of All-Clad:

All-Clad D3 Stainless – Usually when people talk about “All-Clad,” they are referring to All-Clad D3 Stainless, which was renamed “All-Clad D3 Stainless” in 2018. This is the original fully-cladded bestseller. Every pot and pan is made out of a three-layer sandwich (stainless interior/exterior surrounding a core of aluminum). 2.6 mm total sidewall thickness for most pieces, though their skillets are built with thicker bottoms and thinner sidewalls. All-Clad’s patent on bonding stainless steel to aluminum expired years ago, so you can find tons of knockoffs, though most knockoffs are thinner and less heat-conductive, and some have worse warranties, sourcing, and quality control. All-Clad D3 Stainless uses handles that look like “U” shapes if you look at a cross-section. This means that the handle digs upward into your palm if you hold it with just your hand. All-Clad D3 Stainless, D5, C2, MC2/LTD, and Copper Core product lines all use the same handle. In All-Clad’s defense, you can tuck the handle under your forearm to help relieve the stress on your palm, and your thumb has a groove to rest on, which also prevents accidental rotation of the pan. Wrapping a towel around the handle also works. All-Clad’s short handles (like stock pot handles) work fine. All-Clad D3 Stainless pieces (skillets, saute pans, stock pots) have flared rims for easier pouring, but saucepans and French skillets (which are basically the same thing as regular skillets but thinner and with slightly wider bottoms) do not. As an aside, I don’t recommend All-Clad D3 Stainless French skillets due to their thinness and because flared rims make clean pours much easier.

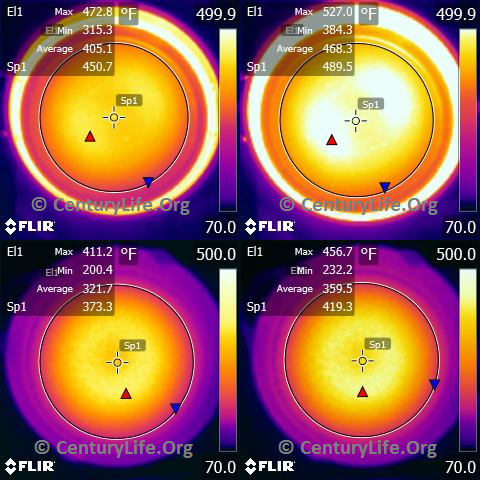

All-Clad D5 – Since All-Clad D5 costs more than All-Clad D3 Stainless, you might think that D5 conducts heat better than Stainless. My testing results disagree; D5 slightly trails Stainless. If we’re charitable we can call it a tie. Despite the thin layer of stainless steel embedded in the aluminum core, D5 is the same thickness as regular All-Clad D3 Stainless (both are about 2.6 mm thick), which means you get less heat-conducting aluminum in D5 than you do in Stainless. So compared to All-Clad D3 Stainless, you get slightly worse heat conduction, and modestly better heat retention (i.e., D5 warms up and cools down more slowly than All-Clad D3 Stainless). Aside from thermal differences, D5 has a few other improvements: a little thumb rest on bottom side of the handle, additional structural strength from the thin layer of steel embedded in the core, and flared rims at the top edges of all D5 pans to make for easier, drip-free pouring (All-Clad D3 Stainless saucepans don’t have flared rims though skillets, saute pans, and stock pots do). Lastly, D5 has brushed finish (less-polished stainless steel on the outside, giving it a less shiny and more matte appearance that hides scratches better). Brushed D5 is also known as BD5 (“brushed D5”). If you are deciding between D5 and Stainless, the D5 is slightly better for the reasons above. But for a bigger step up from All-Clad D3 Stainless, you’d want to go Copper Core.

All-Clad D7 (I review it here) – Discontinued sometime around 2018. Came out in 2014 in 6 and 8 quart casserole/stock pot sizes; expanded in 2015 to skillets and saute pans. Micrometer measurement indicated 3.76 mm thickness, with seven alternating layers of stainless steel and aluminum (the interior and exterior layers are stainless steel). They have heavy, thick lids. This is All-Clad’s attempt to get more people to buy their pots instead of Le Creuset or Staub French ovens, but All-Clad’s prices ($300-400) are steep. Get either a) a cheaper, thinner cladded stainless stock pot that would heat up faster, such as regular All-Clad D3 Stainless or D5; or b) an enameled cast iron Dutch oven which better tolerates long braises–even acidic and salty braises.

All-Clad Copper Core – (I review it here.) Copper Core is made out of a five-layer sandwich: stainless, aluminum, copper, aluminum, and stainless. For decorative reasons, All-Clad cuts into the exterior of the pan to expose the copper in a thin band around the perimeter of the pot or pan. Thus the pan’s decorative band is missing the exterior aluminum and stainless layers. The copper core has about the equivalent of ~0.9 mm copper, making it slightly more heat conductive than All-Clad D3 Stainless. But the price is steep, and you can get even heating performance similar to Copper Core with aluminum-based cookware, as long as the aluminum is thick enough. For example, All-Clad MC2

(described below) actually spreads heat better than Copper Core. On the other hand, copper heats up and cools down somewhat faster than aluminum, so if that’s a big issue for you, then consider getting Copper Core anyway. All Copper Core pieces have flared rims for easier pouring. By the way, I would be wary of buying Copper Core knockoffs, because copper is harder to bond to steel than aluminum is. Every Copper Core knockoff I’ve seen either a) has been so thin that it doesn’t outperform regular All-Clad D3 Stainless, or b) had warping or layer-separation issues even brand new right out of the box.

All-Clad Master Chef 2 (aka MC2) – (I review it here. Note that it was discontinued sometime around 2018 and replaced with All-Clad LTD2, which is basically the same thing, but more expensive and with anodized exterior to protect against scratches better.) Aluminum vessel with stainless steel interior coating. The aluminum layer is thick and thermal testing shows that MC2 heats more evenly than All-Clad D3 Stainless, D5, and Copper Core, and is in the same ballpark as C2. However, the exposed outer aluminum means that MC2 will accumulate scratches easily and can not be put in the dishwasher or be used on induction stoves. Micrometer measurement of the MC2 12-inch skillet is roughly 3.45 mm total thickness, of which at least 2.9 mm is aluminum. (Other pieces are thinner, presumably because they don’t have to deal with the much higher temperatures and thermal stresses that skillets must endure; e.g., the 8-quart stock pot is about 2.8 mm thick, and the 3-quart saute is about 3.23 mm thick.) MC2 costs a little less than All-Clad D3 Stainless and is the best bang for the buck in All-Clad’s lineup, if you are okay with its drawbacks. Note that like with All-Clad D3 Stainless, MC2 skillets, saute pans, and stock pots have flared rims, but not saucepans.

All-Clad Copper Clad (aka C2) – (I review it here. Please note this was discontinued sometime around 2018. Apparently there isn’t much of a market for expensive, thin copper cookware.) This product line launched in 2014 but looks like it got discontinued in 2016. There are only two layers: stainless steel interior and copper exterior. The handles are stainless. All pieces have flared rims for easier pouring. The short story is that we can’t recommend it. C2 has a copper exterior and all that entails: copper-exterior cookware, if left uncleaned and unpolished will turn into a dark, matte brown over time as the copper oxidizes, and you don’t even get that much copper for the trouble (about 1.2 mm copper layer thickness). The better alternatives to All-Clad Copper Clad in the All-Clad product line are MC2 and Copper Core. MC2 heats about as evenly as C2, isn’t that much less responsive to changes in burner strength, and costs much less. Copper Core doesn’t perform quite as well as C2, but it has a stainless steel exterior and interior (induction-compatibility, lower maintenance/higher corrosion resistance, and higher scratch-resistance).

All-Clad Nonstick (e.g., All-Clad NS1, All-Clad D3 Stainless or D5 / D5 Hybrid with nonstick). The short story is that All-Clad’s nonstick (PTFE) products are mediocre and overpriced. If you want excellent, affordable nonstick with lifetime warranty, I highly recommend Anolon Nouvelle Copper nonstick (I review it here) because it has a thick base with great heat distribution and retention and resistance to warping, no rivets to accumulate grime, and the best nonstick coating I’ve ever used. In comparison, All-Clad nonstick costs more, has worse heat distribution and handles, has a lower-quality nonstick coating, and does not have a nonstick coating on the rivets, so food sticks to the exposed rivets. All-Clad also introduced D3 Armor, which is built like All-Clad D3 Stainless but with raised bumps. In theory this reduces sticking slightly, but I’ve used similar bumpy-bottom stainless, and the bumps do not make much difference in stickiness. A better solution is to get an actual nonstick pan to supplement your regular, non-bumpy stainless pans.

Q: Is All-Clad induction-compatible?

A: All-Clad with stainless bottoms are generally induction compatible; in fact, some All-Clad product lines have been induction-compatible since at least the mid-1990s. Most stainless-steel-bottomed cookware pieces of any brand are induction-compatible. Magnetic stainless (400 series, usually 430 stainless, also known as 18/0) costs less to produce than 304 Stainless (commonly referred to as 18/8 or 18/10 stainless). Using cheaper magnetic stainless steel exteriors allows manufacturers to a) claim induction compatibility and b) reduce costs at the same time. The only drawback is that magnetic stainless steel is less corrosion-resistant, so don’t let your cookware sit in puddles of water overnight. You can easily check to see if a pan is induction-compatible by seeing if a magnet will strongly stick to the bottom of the pan. If the magnet strongly sticks, then the pan is induction-compatible.

Q: Why does All-Clad cost so much? Why is All-Clad so expensive?

A: Multiple reasons:

First, All-Clad is not a charity; it’s a business. All-Clad charges what the market will bear, not what the product costs to make.

Second, the cost of labor and regulatory compliance is higher in the USA than China, and All-Clad presumably spends more than Chinese-based companies on quality control, marketing, regulatory compliance (environmental, workplace safety, etc.), and materials sourcing. All-Clad sources all of its stainless steel within a 500-mile radius of its Pennsylvania factory. These extra costs ensure that All-Clad products are high-quality.

Many companies–even big-name companies–merely import product from Chinese factories for resale, and often don’t spend enough resources to verify quality after the first batch. It takes money and expertise to continuously ensure good quality: products don’t bend out of shape with use, do not contain harmful or radioactive chemical contaminants, are polished properly, and use high-quality stainless steel. If a company doesn’t operate its own factories in China, it could end up like Lumber Liquidators, which sold floorboards with excessive formaldehyde that leaked into the air of the homes it was installed in, which increased consumer cancer risks among other things. Lumber Liquidators told its Chinese partner that it wanted in-spec product, but received out-of-spec product anyway, and nobody caught the discrepancy until end-users started getting sick. There are many more examples of Chinese and Indian exports containing toxic or radioactive chemicals, and even more examples of Chinese cookware falling apart, such as handles breaking off while in use, frying pans exploding or popping rivets off, enamel coatings cracking and flying off, ceramic roasters shattering, lids breaking, etc. In contrast, chemical contamination and structural failure are almost unheard of with cookware made in the USA/EU, such as All-Clad and Le Creuset.

Q: What are some alternatives to All-Clad D3 Stainless?

A: Often this question is asked when one wants All-Clad performance and construction (interior/exterior stainless sandwiching a heat-conductive core of aluminum/copper/etc.) for less money.

Among All-Clad’s product lines, I’d avoid D5/C2/Copper Core/nonstick for reasons stated above–they are offer less bang for the buck than All-Clad D3, also known as All-Clad Stainless (the basic and most popular style: stainless-aluminum-stainless sandwich) and All-Clad MC2

(discontinued and replaced with the nearly-identical All-Clad LTD2; stainless cooking surface with a thick outer layer of aluminum). Get MC2/LTD (I reviewed it here) if you have a gas or electric coil stove and don’t intend to switch to induction, if you don’t mind hand-washing, and if you don’t care if the bottoms of your pans get very scratched up. Otherwise, get All-Clad D3 Stainless, which performs worse but is induction-compatible, dishwasher safe, and won’t get as badly scratched up on the bottom.

If you’re willing to consider other companies’ products, you have more options. Cuisinart MultiClad Pro (aka Cuisinart MCP; I reviewed it here) is the cheapest product that still heats as evenly as All-Clad D3 Stainless and still has the high-end features of All-Clad D3 Stainless: flared rims for easier pouring, helper handles on the heavier pieces so you can use both hands when washing or moving the pan to/from the oven, and all-stainless-steel construction (handles, lids) for high oven temperatures and transferring food between stovetop and oven, like some recipes call for. Think of Cuisinart MultiClad Pro as All-Clad D3 Stainless made in China, with better handles, with arguably less corrosion resistance (it’s apparently still very rugged though–my heavily-used 3-quart MCP saucepan has given years of service since 2010, with no trace of rust or pitting inside.

I personally used the 12-piece MCP set for years and can vouch for its quality. In fact, one of our most-used pieces of cookware is the aforementioned Cuisinart MCP 3-quart saucepan

, which comes with the Cuisinart MultiClad Pro (MCP) 12-piece set

in addition to a steamer basket intended to fit on top of it. Despite all the abuse that the 3-quart saucepan has taken over the years, including my accidentally letting it boil dry during a long telephone call in one instance, and boiling dry for 11 minutes on high heat in another, and my burning rice in it, it has not warped. It’s accumulated some scratches but performs like new. Compare the price of that 12-piece MCP set

to the price of the 10-piece All-Clad D3 Stainless set

and you can see why MCP is so popular.

You could go cheaper than Cuisinart MCP, but you don’t save much money, especially for something that you may use for the rest of your life. And you often give up thermal performance and features, such as steel lids. (Most high-end cookware products use steel lids instead of glass lids. Glass lids are cheaper to make than steel lids, but most glass lids can’t take high oven temperatures, which restricts the kinds of things you can cook unless you pay extra for aftermarket steel lids which may or may not fit well.) You also give up the relative safety of having big-company oversight of Chinese production–Cuisinart is one of the largest cookware manufacturers in the world. China is a country that has a history of scandals ranging from buildings that collapse (37 Chinese-built bridges collapsed from 2007 to 2012) to toxic baby formula to fake chicken eggs, so you probably want to buy from a company that will make sure that the factory isn’t skimping on the quality of the stainless steel or falsifying its safety certifications.3 I test all of my cookware, clothes, etc. for radioactivity. Nothing has exhibited unusual radioactivity thus far, so I wouldn’t be too paranoid about radioactive cookware. I’d be more concerned about a Chinese cookware company delivering out-of-spec stainless that is more vulnerable to rust/corrosion, or delivering something with chemical contaminants, like the contaminated laminate once sold by Lumber Liquidators, which go undetected because the importer is too cheap or incompetent to do proper quality control (a few spot checks is not enough).

The old saying “buy cheap, buy twice” applies here: if you buy too cheap, you will just end up regretting it and replacing it later at additional expense compared to if you had bought the better product in the first place.

If you are interested in learning about a broader spectrum of All-Clad D3 Stainless alternatives, I’ve grouped some of the major alternatives into tiers:

Non-All-Clad alternatives, from best to worst:

1. Top-Tier All-Clad D3 Stainless Rivals (better than All-Clad D3 Stainless performance):

Among products built like All-Clad (stainless inside and out, with heat-conductive core in the middle), Demeyere’s Proline skillets are unrivaled. Demeyere’s Proline skillets perform about as well as 2 mm copper skillets–but without the maintenance of copper (most high-end copper pieces have cast iron handles that can rust if not seasoned; copper scratches more easily than stainless steel; copper oxidizes into a matte brown if not cleaned regularly; copper can’t go into the dishwasher; copper is not induction-compatible; and copper cookware almost always uses rivets, which can be hard to clean around).

- If you can get only one piece of Demeyere, start off with a skillet: the Demeyere Proline 5-Star 11″ Frying Pan

or the Demeyere Proline 5 Star 12.6 Inch Fry Pan

. (I review both here.) The piece of cookware that undergoes the most thermal stress is the skillet, since it has to deal with high frying temperatures, so it makes sense to splurge there instead of, say, a stockpot that would only be used to boil water.

- Demeyere also makes non-skillet products in their Atlantis product line

. The large conic sauteuses

are 3.3 mm thick overall (much thicker than All-Clad’s 2.6 mm), and then aluminum layer thickness is 2.2 mm (compared to about 1.7 mm for All-Clad D3 Stainless). That’s 30% more aluminum, for better heat distribution.

- The rest of the Atlantis product line has straight sidewalls and is not built like All-Clad; there is no heat-conductive metal running up the side. Instead, Demeyere bonds 2 mm thick copper discs to the bottom and then welds a three-layer magnetic stainless steel wrapper over the copper, for protection and induction-compatibility. The 2 mm of copper performs similarly to 4 mm of aluminum, but is more responsive when you turn your burner up or down.

- In my experience, if you are okay with less capacity, you can get away with just the Proline skillet, but if you want a saute pan as well, then the Atlantis saute pan is a good product; saute pans undergo the second-highest amount of thermal stress after skillets, and you may want a big, roomy saute pan to help brown lots of stuff or to cook down lots of leafy greens. I would skip the rest of the Atlantis stockpots and saucepans because you already have great coverage with just a Proline skillet and Atlantis conic sauteuse and saute pan. You can do everything from steaks to oatmeal to leafy greens using those three pans. You can add a less-expensive clad stock pot from another company if necessary, such as the Cuisinart MCP66-28N MultiClad Pro Stainless 12-Quart Stockpot with Cover

.

USA-made Vollrath Tribute (I review it here) is built similarly to All-Clad, but the larger pieces are built thicker than All-Clad Stainless. For instance, the Vollrath Tribute 14-inch pans

are advertised as 6-gauge, whereas the 12-inch version

and the 10-inch version

are both advertised as 8 gauge, or 3.14 mm according to my micrometer. Vollrath Tribute prices are priced slightly lower than All-Clad Stainless, but the 8-gauge and 6-gauge pieces deliver better performance. Tribute comes with stainless steel handles, but a few pieces have optional silicone-covered stainless steel handles rated to 450 degrees F (232 degrees C). The main downsides for Vollrath Tribute: a) four rivets per handle (instead of two like most others) which is overkill for home kitchens, so all you’re really getting is more food particles stuck around more rivets; b) no lids are included, and if you try to use another brand of lid, you’ll find that they don’t fit that well in Tribute pots thanks the unforgiving angle of Tribute rims–and even if you pay for the high-priced Vollrath Tribute lids, even those lids aren’t that thick or close-fitting, and they aren’t oven safe past 180F (less than boiling temperature!); and c) Vollrath Tribute has poor ergonomics. Even the heavy Vollrath Tribute pieces like the 14-inch fry pan don’t have helper handles. Tribute saute pans lack helper handles unless they are 6+ quarts, at which point they are nearly as big as some stock pots. On some Tribute pieces, there is an additional drawback: the metal that attaches the handle to the pan is shaped like an upside-down “U,” which is uncomfortable to grip, so you have to keep your hand well away from the body of the pan; this means you can’t deal with the lack of a helper handle by tucking the main handle under your arm. This adds to discomfort and perceived weight of the pan. That metal piece hurts after cooking, too: every time I hand wash my 12 inch Tribute skillet, that upside-down U digs two lines into my hand. Vollrath Tribute is good value for the money if you can live with the drawbacks. Personally I’d choose another brand instead.

The Demeyere Industry5/5-plus/Zwilling Sensation product line (the same thing with different handles) performs somewhat better in terms of even heating than All-Clad Stainless due to its extra thickness (3 mm vs. 2.6 mm). Industry5 also has a better and less-sticky finish, no rivets to trap food particles, and a more comfortable handle. They are made in Belgium and priced competitively with All-Clad Stainless or D5. However, for not that much more money you could cut to the chase and get Demeyere Atlantis and Demeyere Proline Skillets, both of which are a much bigger jump in quality compared to All-Clad D3 Stainless.

2. Mid-Tier All-Clad D3 Stainless Rivals (about the same as All-ClD3 ad Stainless performance):

Cuisinart MultiClad Pro (MCP)

(I review it here) is ~2.6 mm thick, same as All-Clad D3 Stainless but with a very slightly lower ratio of aluminum to stainless, so it performs very slightly worse in terms of evenness of heating. MCP has flared rims on all pieces, to minimize drips down the side while pouring. There is an older, discontinued MCP line

; the newer MCP products have the letter “N” in their product numbers. The only difference is that the newer “N” product line has slightly more comfortable handles. All of my references to Cuisinart MCP are to the new “N” product line, because there is no real reason to buy the older product line. All MCP is made in China with lifetime warranty. Cuisinart MCP is the best value among the many Chinese All-Clad D3 Stainless knockoffs out there, but it’s made in China, if that’s an issue for you.

As I mentioned above, one of our most-used pieces of cookware is the Cuisinart MCP3-quart saucepan, which comes with the Cuisinart MultiClad Pro (MCP) 12-piece set

. Despite all the abuse that 3-quart saucepan has taken over the years (including my accidentally letting it boil dry multiple times, especially one instance where I let it boil dry for 11 minutes on high heat), it has not warped. You can basically think of MCP as the cheapest clone of All-Clad Stainless that still retains all of the features (flared rims on all pieces–whereas All-Clad only has flared rims on non-saucepan pieces, helper handles, oven-safe steel lids) and most of the performance in terms of even-heating. Cuisinart MCP lids are not magnetic and thus presumably use SAE/AISI 304 (18/8 or 18/10) or at least SAE 200-series stainless steel (18/4), but All-Clad lids are sometimes made out of less corrosion-resistant 18/0 stainless based on my magnetic testing. And MCP handles are decently comfortable.

If the “made in China” part bothers you, you can pay extra to get French-made Cuisinart French Classic (I review it here) which is the same thing with slightly different and more comfortable handles. The downsides: no flared rims (which means a higher risk of dripping during pours) and a somewhat higher price. Based on my thermal tests, Cuisinart French Classic performs the same as Cuisinart MCP.

Mauviel M’Cook 5 Ply Stainless Steel is 2.6 mm thick (sidewall thickness, measured via micrometer; and this matches up with Mauviel’s advertising copy which claims that M’Cook stainless is 2.6 mm thick). Made in France, this line is priced high for something that is basically an All-Clad Stainless clone that doesn’t heat quite as evenly, since it has a slightly lower ratio of aluminum to stainless steel. The handles are arguably even worse than All-Clad’s, being thin and prone to unwanted rotation. If you want a version of All-Clad made in France, I would suggest getting Cuisinart French Classic instead.

Tramontina Tri-Ply Clad (I review it here) is ~2.6 mm thick, like All-Clad and Cuisinart MCP, but performs (very) slightly worse than both. The handles are decently comfortable. The price is about the same as Cuisinart MCP for individual pieces and a little cheaper as a set, but a) Tramontina doesn’t have flared rims, so it’s much easier to spill liquids down the sides of your pots and pans while pouring; b) Tramontina recently changed the shape of their 12-inch skillet into a semi-wok-like shape with a lot less flat bottom surface area, which makes it a lot less useful for most people; and c) the only cladded piece I’ve ever owned which has warped has been a Tramontina Tri-Ply Clad stock pot. In all fairness though the company did replace it under warranty. By the way, “Tramontina Tri-Ply” is not the same as “Tramontina Tri-Ply Clad.” If it doesn’t have the word “Clad,” then it just has an aluminum disc base and does not have any aluminum going up the sidewalls.

3. Third-Tier All-Clad Stainless Alternatives (worse than All-Clad Stainless in performance):

Calphalon’s Tri-Ply Stainless is a paltry ~2.12 mm thick, though the Contemporary Stainless

line is a more respectable ~2.36 mm thick. Both are thinner than All-Clad Stainless (~2.6 mm). Both have breakable glass lids, and the Contemporary Stainless line does not have flared rims, so you get messier pours. From previous thermal testing of saute pans, the Contemporary line is worse than All-Clad Stainless in terms of heat-spreading performance. The even-thinner Tri-Ply Stainless line performs even worse. Both product lines are made in China. (Regarding Calphalon AccuCore

which is discontinued as of 2016: AccuCore’s copper layer is visibly thinner than All-Clad Copper Core, and the entire AccuCore thickness is only about 2.13 mm thick. Until further testing, I can’t confirm anything, but I would be surprised if Accucore performed significantly better than All-Clad Stainless. If you must have a copper core, take a look at All-Clad Copper Core

instead, which gives you a much thicker copper layer without watering it down with aluminum like Calphalon did. Calphalon’s Accucore is made in China.)

Cooks Standard (I review it here) is a relatively young brand that imports Chinese All-Clad Stainless

knockoffs. The 12-inch skillet’s sidewall thickness is 2.44 mm (via micrometer measurement). Cooks Standard did worse than the thicker All-Clad knockoffs in thermal testing. Cooks Standard uses durable, stainless steel lids instead of glass lids that can’t take high oven temperatures. In sum, you don’t save much money by buying this over Cuisinart MCP (especially if you factor in warranty–Cuisinart will still be around 20 years from now, but I’m not sure about the Chinese importer behind Cooks Standard), yet you lose some evenness of heating. Furthermore, I’ve bought 2 pieces from them for testing, and one came with a long scratch near the exterior rim, as well as chromium oxide residue on the bottom left over from polishing. The logo etched into every lid is tacky-looking. If you absolutely must have clad but you absolutely refuse to pay a dime more than necessary, Cooks Standard is for you. Personally I would go for at least Cuisinart MCP: don’t go out to a restaurant for dinner one time, and that will more than pay for the entire price difference between Cooks Standard and Cuisinart MCP (I review it here). Or else get a mix-and-match set with MCP skillet/saute/saucepan and Cuisinart Professional Series Stainless for everything else.

Other Tri-Ply Stainless Brands:

There are many other brands of tri-ply stainless–too many to list here. After All-Clad Stainless patents expired, seemingly every cookware company in the world contracted with some Chinese factory to crank out All-Clad Stainless knockoffs. Le Creuset for instance, has Le Creuset All-Clad knockoffs made in China (recently changed to Portugal), apparently trying to parlay Le Creuset’s good reputation for enameled cast iron dutch ovens into sales of overpriced tri-ply. What’s the point of buying Le Creuset’s tri-ply if they are going to charge you almost as much All-Clad and not even make it in USA or France? And if you are okay with Chinese tri-ply, you could get Cuisinart MCP, which performs just as well, for much less money.

Another example of companies trying to parlay their brands into a price premium for tri-ply is Williams-Sonoma’s Open Kitchen (a paltry 2.18 mm thickness measured via micrometer on the 3-quart saute pan; also note that the product line does not have flared rims). People might buy the Open Kitchen pans thinking that they are getting good quality, when in fact they are getting second-rate tri-ply. Similarly, Viking contracts with Clipper (an importer of cheap Chinese cookware) to import shoddy cladded cookware that is only ~2.16 mm thick and doesn’t even have flared rims. (Many years ago, Viking’s clad used to be made by Demeyere and was top-notch. I guess Viking is still trading on that old reputation because the prices of their new, thin, Chinese stuff is outrageous.) Sur La Table Tri-Ply Stainless (their store brand; click anywhere outside of the pop-up box to get rid of their annoying pop-up ads) is made in China and doesn’t perform any better than cheaper clones like Cuisinart MCP and yet cost more.

The list goes on and on. I’ve examined many Chinese All-Clad knockoffs other than the ones I mentioned above, and almost all of them are between 2.2 and 2.5 mm thick compared to the ~2.6 mm of All-Clad Stainless. These thinner knockoffs either performed worse, cost more, lacked features like flared rims and stainless steel lids, or all of the above. Sometimes these spammy Chinese knockoffs are so similar to each other that I think they must be coming out of the same factory, with different logos stamped on the bottoms depending on which American company decided to import them.

4. Non-Stainless Alternatives:

For sake of completeness, there are non-metallic alternatives that have thick aluminum or copper sidewalls as well. Such alternatives include:

- Nonstick aluminum pans

- Ceramic “nonstick”-ish aluminum pans

- Copper

All three are different enough that they aren’t directly comparable to All-Clad Stainless:

- Nonstick aluminum can perform like All-Clad Stainless, or even better if you get the really thick nonstick aluminum pans. However, the cheaper ones don’t last as long because they warp–their bottoms become less-flat. Nonstick is also fragile: it will offgas at 400F making it questionable in terms of oven-readiness, and all nonstick wears off eventually, which is why I don’t recommend spending too much money on nonstick pans, no matter how good they are otherwise. Aluminum pans without magnetic steel bottoms are not induction compatible. Usually nonstick pans are not dishwashable. Examples of nonstick pans: Anolon Nouvelle Copper, T-Fal Professional

- Ceramic is a popular alternative to nonstick, so it’s used as a layer over aluminum pans sometimes. Ceramic can chip, so it requires more coddling than rugged stuff like All-Clad Stainless. Many people also report that ceramic nonstick loses its nonstick qualities after just a few months of hard use, though part of that may be due to users who overheat their pans. Some manufacturers admit to this problem, if you read between the lines of their PR statements. For example, Berndes, a German maker of ceramic-coated pans, confesses on its website that “[c]eramic coatings are not directly comparable to non-stick coatings. Although they come with good non-stick properties at first, these decline after a short period of use and cleaning. … over time, the non-stick properties wear off, a process that is accelerated by cleaning in a dishwasher.” Furthermore, aluminum pans without magnetic steel bottoms are not induction compatible. Nevertheless, they are viable for skillets. I wouldn’t bother getting ceramic for anything other than skillets, because you don’t need nonstick pots to boil water or make sauces and such. Examples of ceramic-coated pans: Berndes SignoCast/Vario Click, Ozeri Green Earth

- Copper pans are very high performance, but come with various drawbacks. Tin-lined copper isn’t nearly as rugged and oven-ready as stainless-lined copper, as it starts to soften at low frying temperatures and melts at high frying temperatures. Tin-lined costs less but requires re-tinning every several years so it can easily cost more than stainless-lined copper in the long term. As for stainless-lined copper, copper requires more maintenance to keep from looking terrible (oxidized copper looks like a matte, dark brown or black) and usually costs far more than All-Clad Stainless. Also, most thick copper has brass or cast iron handles which get hot during cooking. Cast iron handles require particular care, as you need to make sure they get oiled and don’t get put away wet, else you run the risk of rust. And copper without magnetic steel bottoms don’t work with induction. Lastly, copper is also not dishwashable. Examples of copper cookware: De Buyer Prima Matera

Therefore we won’t explore those alternatives in this article as they come from a different design philosophy where durability/dishwashability/induction-compatibility aren’t anywhere near All-Clad Stainless. (If you are interested in even-heating nonstick, though, I can’t say enough good things about Anolon Nouvelle Copper nonstick. It’s got the most even-heating base I’ve ever seen in any PTFE/Teflon nonstick product line, its nonstick coating is the least-stickiest I’ve ever encountered, and it’s even induction-compatible.)

CONCLUSION

If you’re looking to build a clad cookware set, then the cheapest good clad is the 12-piece Cuisinart MultiClad Pro set which I have used since 2010; I continue to use the 3-quart saucepan from that set just to see if it will corrode (it hasn’t). In my experience, Cuisinart MultiClad Pro

(I review it here) performs as well as All-Clad Stainless

. The main drawback being that Cuisinart MCP is made in China, but at least Cuisinart is a major company that controls its own supply, unlike smaller brands that just import from unsupervised Chinese factories.

However, All-Clad Stainless and similar knockoffs like MCP are not “the best” cookware, no matter what their marketing materials claim. The thickness of the aluminum in All-Clad Stainless/Cuisinart MCP is only ~1.7 mm at best, which is comparable to cheap, thin nonstick aluminum pans. That’s not bad thermal performance, and since you have stainless cladding instead of cheap nonstick coatings, you get higher durability (no nonstick material flaking off, and the cladded pan is far less likely to warp or bend), far higher heat capacity (so the pan doesn’t crash in temperature as much when you toss in a steak), and dishwasher compatibility.

Therefore you may want to get a Cuisinart MCP or All-Clad Stainless set and supplement it with a better/larger skillet like a Demeyere Proline skillet.

FOOTNOTES